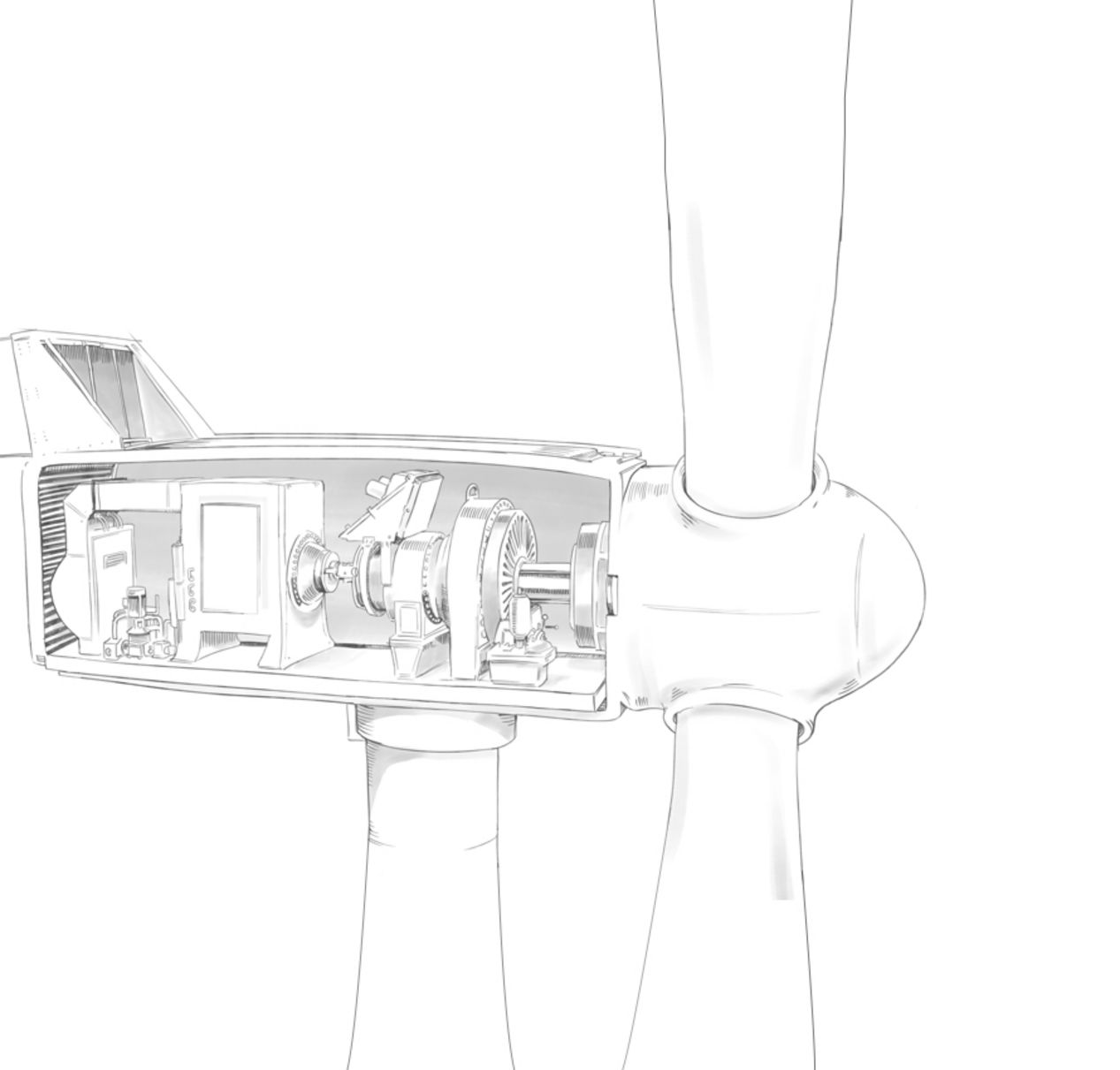

Cooling Systems for Wind Power: Onshore and Offshore

Innovation and experience

Since one century

Innovation and experience

Since one century

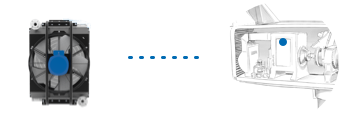

Radiator for generator, converter and inverter cooling

Coolant cooler with fan shroud, motor/fan support and induction (asynchronus) motor

Special Features: Complete system with long lifetime due to flexible air fin profiles

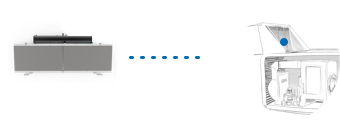

Passive coolant coolers

Coolers and expansion tank

Special Features: No fans needed, bar & plate coolers (full frame not needed), connection coolers with plug & seal elements for easy service of single coolers

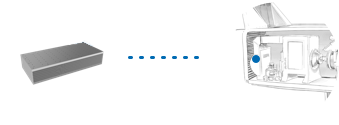

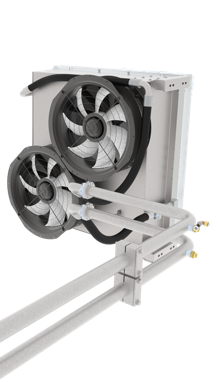

Active gearbox cooling

Coolers, fans, air duct and piping

Special Features: No frame, integrated thermo bypass, longlife flex profiles on air side

Air-to-air cabinet cooling

Cabinet cooler custom made

Special Features: Safe separation of outside and cabinet air for protection class IP65/66, maintenance free, excellent heat transfer with low pressure drop due to variety of available fins, high design flexibility for medium flow paths

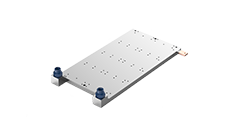

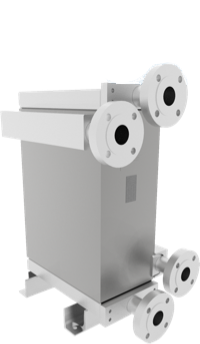

Liquid cooled inverter / converter cooling

Heat sink, if necessary including pump unit and radiator

Special Features: Optimal and individual thermal dimensioning, minimal thermal resistance between cold plate surface and fluid by the use of special turbulators, no deformation by pressurization, high coolant temperature allows use of space saving and efficient radiators

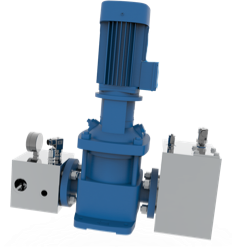

Pump system for coolant or oil

Pump unit with sensors, hoses and piping

Special Features: Reduced maintenance

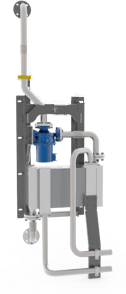

Cooling of transformer oil

Liquid-to-liquid heat exchanger, coolant pump, piping, frames and support brackets

Special Features: Additional (safety) passages ensure no contact and avoid mixing of transformer oil and coolant even in the event of leakage of either of the two circuits

Oil coolers for gearbox cooling

Liquid-to-liquid heat exchanger

Special Features: Stack shell technology

Oil coolers for gearbox cooling

Liquid-to-liquid heat exchanger

Special Features: Modular system in bar plate

Welcome to the AKG World: Cooling Systems for Wind Power

We are a member of APQP4Wind

APQP4Wind is a non-profit organization founded by world-leading Wind Turbine Manufacturers and Suppliers. The background for APQP4Wind is the continuous quality improvement that is needed to keep pace with the ongoing trend towards decreases in the Levelized Cost of Energy within the wind industry. APQP is a well-known concept within the automotive industry and has been the backbone for maturing quality performance at Manufacturers and Suppliers for decades. In the context of APQP4Wind, the concept of APQP is adapted to the business areas and special conditions differentiating wind from automotive. APQP4Wind aims to make the process of product quality assurance demands (APQP) as well as the product release process (PPAP) as clear as possible.

AKG – efficient cooling systems contributing to a greener and sustainable world

AKG supports the decarbonization of the global economy with efficient cooling and thermal management systems for alternative drive concepts and clean energy for customers in selected industries, such as wind energy, electronics and fuel cell cooling. It has always been our goal to improve thermal solutions, starting in 1919 with automotive cooling over the recent past with the cooling of combustion engines in different applications until today’s Green Thermal Solutions. We believe that we can help our customers all over the world to meet their “net-zero” emission targets. AKG Green Thermal Solutions is our approach to help creating a sustainable future.

-

Broschures

Wind energy cooling system

Wind energy cooling system