WindEnergy

Welcome to our special page on WindEnergy!

Innovation and experience

Since one century

Innovation and experience

Since one century

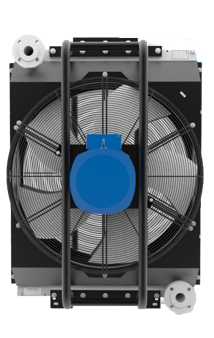

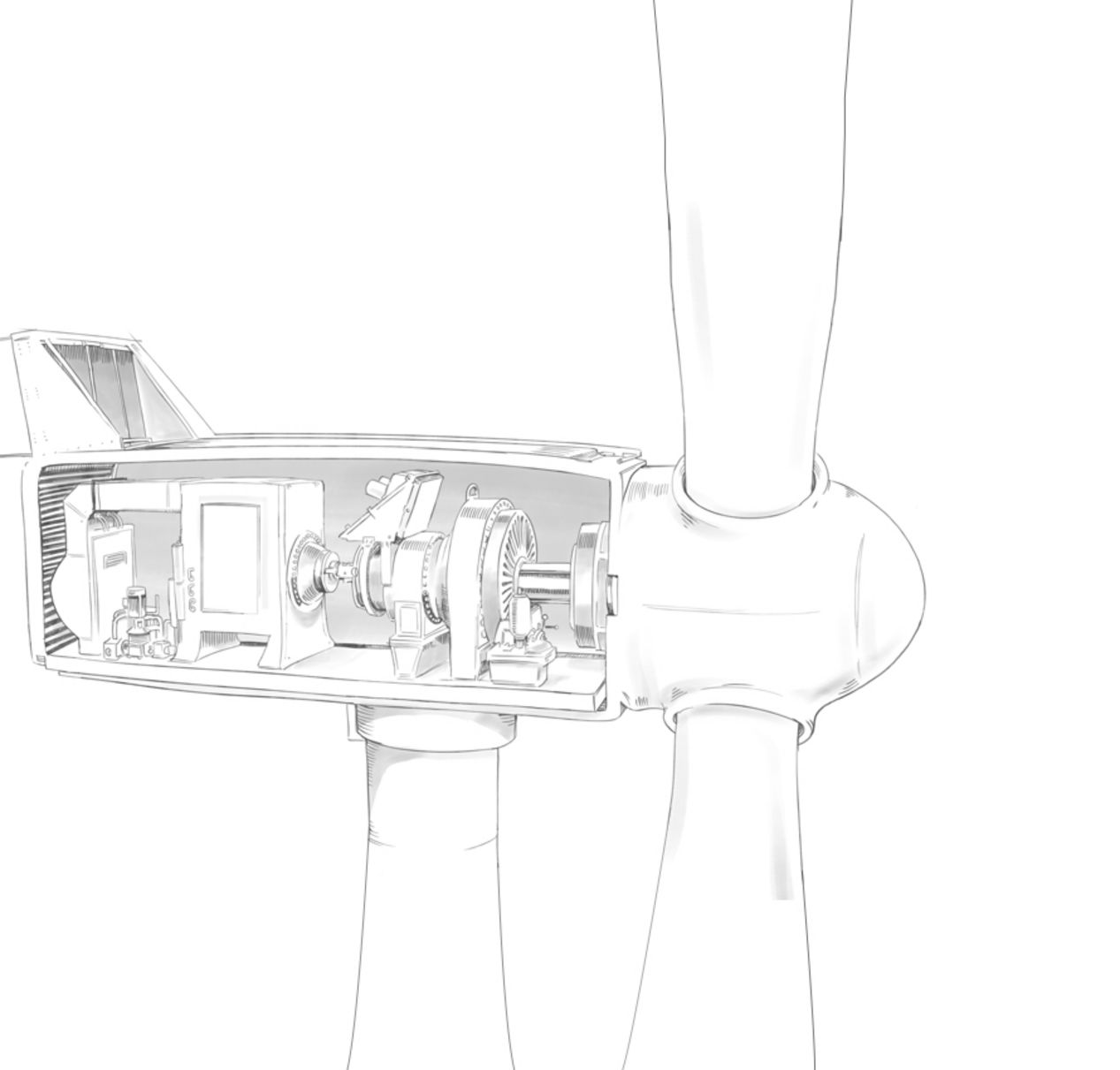

Radiator for generator, converter and inverter cooling

Coolant cooler with fan shroud, motor/fan support and induction (asynchronus) motor

Special Features: Complete system with long lifetime due to flexible air fin profiles

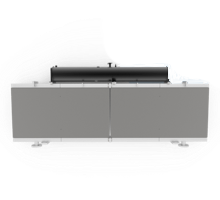

Passive coolant coolers

Coolers and expansion tank

Special Features: No fans needed, bar & plate coolers (full frame not needed), connection coolers with plug & seal elements for easy service of single coolers

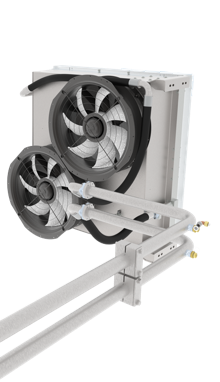

Active gearbox cooling

Coolers, fans, air duct and piping

Special Features: No frame, integrated thermo bypass, longlife flex profiles on air side

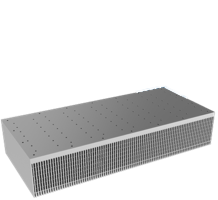

Air-to-air cabinet cooling

Cabinet cooler custom made

Special Features: Safe separation of outside and cabinet air for protection class IP65/66, maintenance free, excellent heat transfer with low pressure drop due to variety of available fins, high design flexibility for medium flow paths

Liquid cooled inverter / converter cooling

Heat sink, if necessary including pump unit and radiator

Special Features: Optimal and individual thermal dimensioning, minimal thermal resistance between cold plate surface and fluid by the use of special turbulators, no deformation by pressurization, high coolant temperature allows use of space saving and efficient radiators

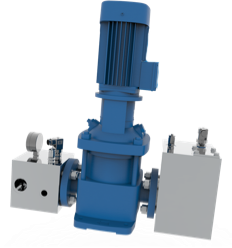

Pump system for coolant or oil

Pump unit with sensors, hoses and piping

Special Features: Reduced maintenance

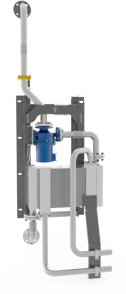

Cooling of transformer oil

Liquid-to-liquid heat exchanger, coolant pump, piping, frames and support brackets

Special Features: Additional (safety) passages ensure no contact and avoid mixing of transformer oil and coolant even in the event of leakage of either of the two circuits

Oil coolers for gearbox cooling

Liquid-to-liquid heat exchanger

Special Features: Stack shell technology

Oil coolers for gearbox cooling

Liquid-to-liquid heat exchanger

Special Features: Modular system in bar plate

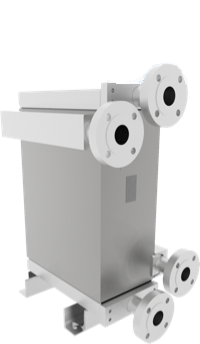

Transformer Safety cooling module

Transformer Cooling modulefor Nordex 4x-6x platform

TECHNISCHE DATEN / TECHNICAL DATA

- abgeführte Wärmeleistung/Heat rejection: 87 kW

MEDIUM Midel 7131 Water Glycol

Durchsatzmenge/: 330 l/min 175-190 l/min

Flow rate

Eintrittstemperatur/: 70°C 55°C

Inlet temperature

Austrittstemperatur/: 61°C 63°C

Outlet temperature

Druckverlust/: 350 mbar 235 mbar

Pressure drop

SBG

- Ein Kühl-Modul für 3 Plattformen / One cooling module for 3 platforms

- Das Herzstück ist der Sicherheits-Wärmeaustauscher von AKG / The core is the safety heat exchanger from AKG

- Das Kühlmodul wird an die thermischen sowie auch an die mechanischen Bedürfnisse des Transformators angepasst/ The cooling module is adapted to the thermal and mechanical requirement of the transformer.

- Hohe Lastwechsel Beständigkeit > 1.500.000 / High load change Durability > 1.500.000