WindEnergy

Welcome to our special page on WindEnergy!

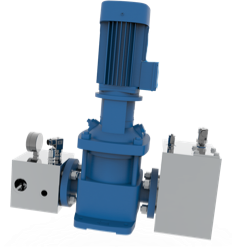

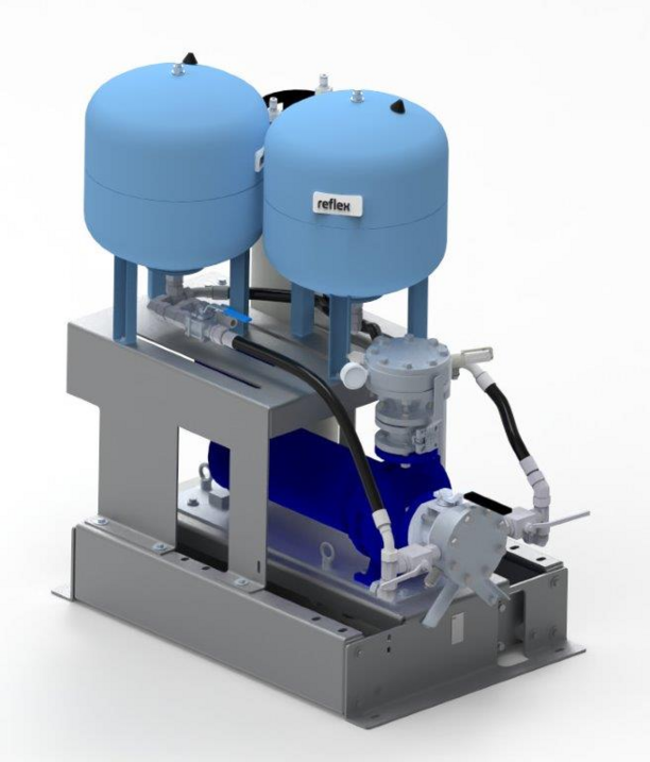

Pump station

TECHNISCHE DATEN / TECHNICAL DATA

- Nennleistung Motor/ rated power of motor: 26 kW

- Frequenz / Frequency: 50 / 60 Hz

- Spannung / Voltage: 400 V

MEDIUM / WORKING FLUID Water Glycol

Durchsatzmenge / Flow rate 1100 l/min

Temperatur / Temperature 20°C

Druck / Pressure 6,5 bar @ 20°C

- An Kundenanforderungen angepasste Konstruktion / Customized design

- Variable Pumpenleistung je nach Kühlleistung/ Variable pump capacity depending on cooling capacity

- Spezielle Zertifizierung nach UL-Standard/ Special certification according to UL-standard

- Angepasste Sensorik nach Kundenbedarf/ Customized sensor technology according to customer requirements

- Durch hohe Korrosionsbeständigkeit geeignet für Onshore und Offshore Anwendungen/ Application suitable for onshore and offshore due to high corrosion resistance

- Optional mit Entionisierungspartrone erhältlich/ Available with an optional deionizing cartridge

- Ausgleichsbehälter / Volume Vessel 2 x 80 l

- Entionisierungspartrone / Deionizing cartridge

Innovation and experience

Since one century

Innovation and experience

Since one century

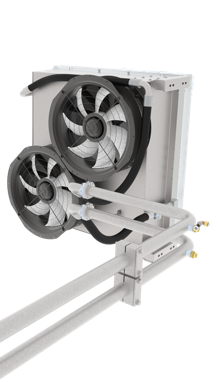

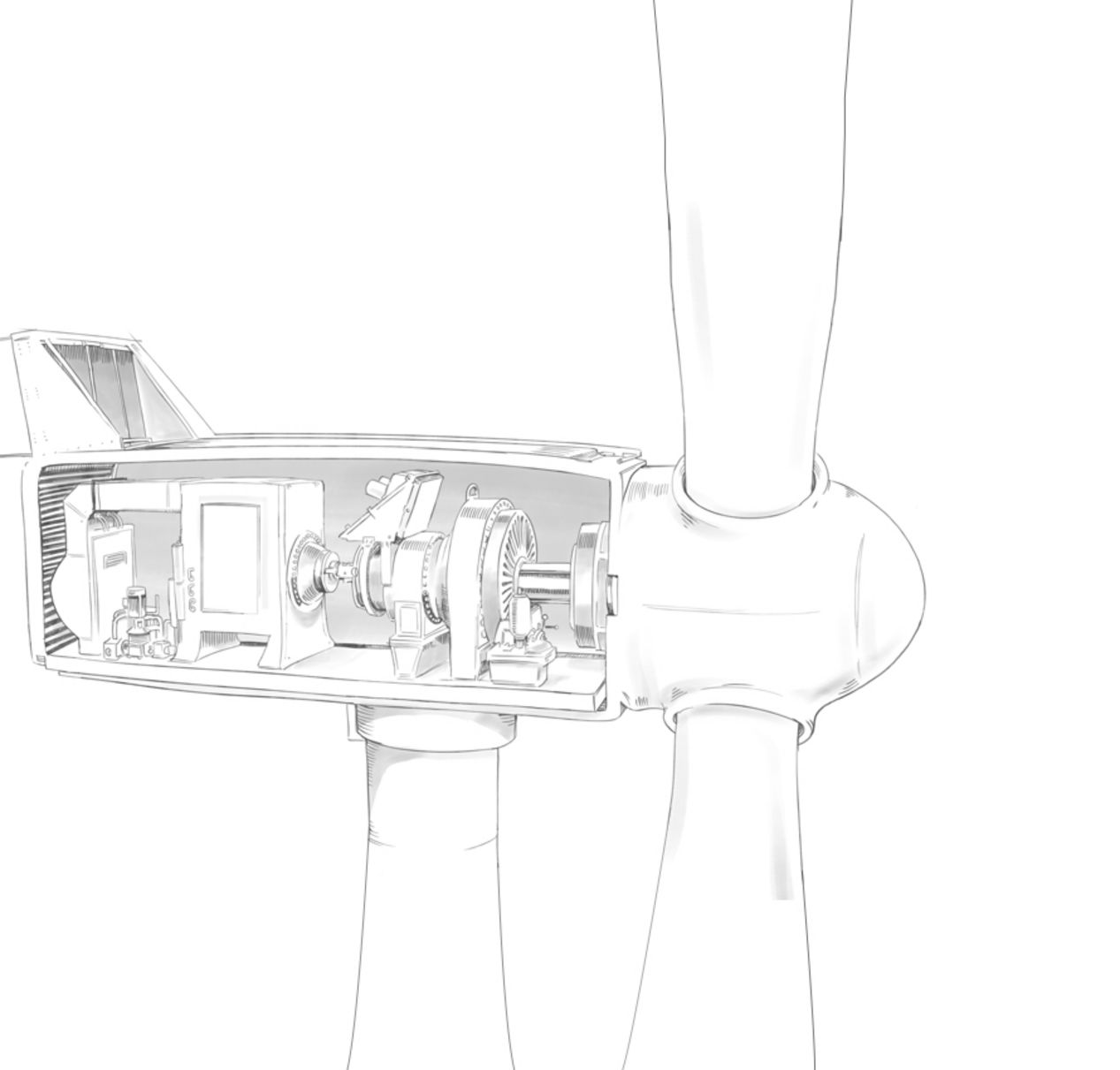

Radiator for generator, converter and inverter cooling

Coolant cooler with fan shroud, motor/fan support and induction (asynchronus) motor

Special Features: Complete system with long lifetime due to flexible air fin profiles

Passive coolant coolers

Coolers and expansion tank

Special Features: No fans needed, bar & plate coolers (full frame not needed), connection coolers with plug & seal elements for easy service of single coolers

Active gearbox cooling

Coolers, fans, air duct and piping

Special Features: No frame, integrated thermo bypass, longlife flex profiles on air side

Air-to-air cabinet cooling

Cabinet cooler custom made

Special Features: Safe separation of outside and cabinet air for protection class IP65/66, maintenance free, excellent heat transfer with low pressure drop due to variety of available fins, high design flexibility for medium flow paths

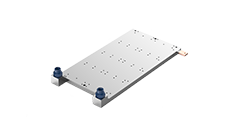

Liquid cooled inverter / converter cooling

Heat sink, if necessary including pump unit and radiator

Special Features: Optimal and individual thermal dimensioning, minimal thermal resistance between cold plate surface and fluid by the use of special turbulators, no deformation by pressurization, high coolant temperature allows use of space saving and efficient radiators

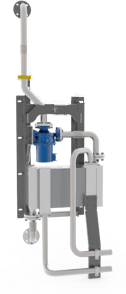

Pump system for coolant or oil

Pump unit with sensors, hoses and piping

Special Features: Reduced maintenance

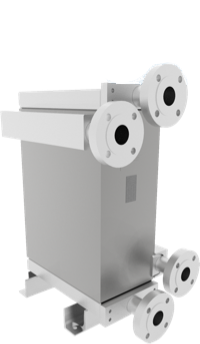

Cooling of transformer oil

Liquid-to-liquid heat exchanger, coolant pump, piping, frames and support brackets

Special Features: Additional (safety) passages ensure no contact and avoid mixing of transformer oil and coolant even in the event of leakage of either of the two circuits

Oil coolers for gearbox cooling

Liquid-to-liquid heat exchanger

Special Features: Stack shell technology

Oil coolers for gearbox cooling

Liquid-to-liquid heat exchanger

Special Features: Modular system in bar plate