Cooling Systems for Rail Vehicle Applications

At AKG, we specialize in advanced cooling solutions that drive the performance and reliability of rail vehicles worldwide. With decades of experience and a commitment to innovation, we offer custom-built heat exchangers and comprehensive cooling systems designed to meet the stringent demands of the modern rail industry. Our products are engineered to ensure optimal temperature regulation, enhance energy efficiency, and comply with international safety standards, making AKG a trusted partner in achieving sustainable and efficient rail transport.

Custom-built heat exchanging solutions

In recent years AKG Thermotechnik International (AKG) has gained application experience with systems in the rail vehicle industry. Based on this wide range of experience in the business, AKG offers its customers more and more complete solutions for cooling tasks.

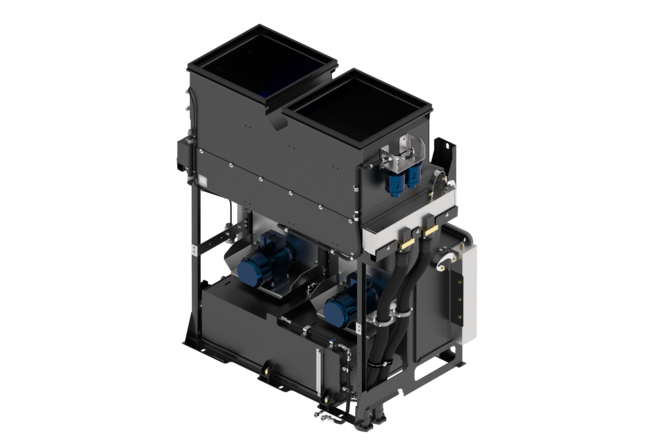

With this strategy, AKG also meets the wishes of many customers who no longer want to assemble the cooling systems for their machines from individual components themselves - as in the past - but instead want to purchase a ready-to-install cooling module, which is delivered directly to the assembly line on time for installation. This strategy involves a shift of design, engineering, procurement, assembly and testing activities from the customer to AKG, resulting in significantly more effort than the sale of individual coolers. AKG does this effort to offer its customers more than our competitors.

Our focus on system solutions also involves cost-saving measures by integrating individual components into larger assemblies, ensuring that the overall system solution remains economically viable. Components that were once separate can now be incorporated into the radiator collection box or welded to the radiator itself. To support this strategy, AKG has assembled a team of experts in various disciplines, including noise reduction, strength calculation, fans, hydraulic and electrical drives, sensors, vibration, and bearing support. These specialists assist our sales force in acquiring and processing system projects, ensuring top-tier solutions for our clients.

Rail Vehicle Cooling

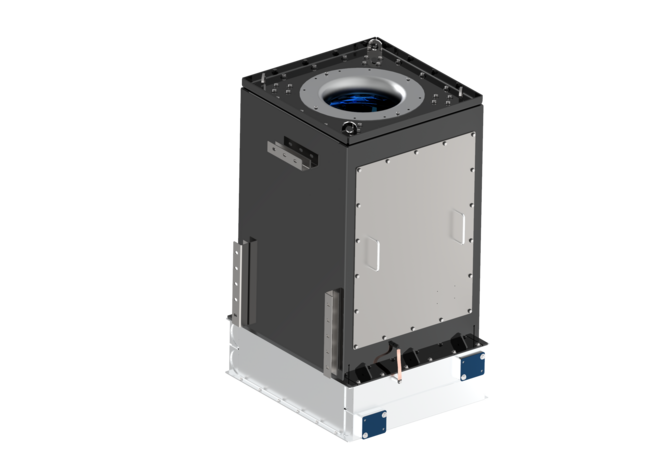

When it comes to cooling rail vehicles, AKG offers you the answer to the question of a reliable and robust cooling solution customized to your needs. Fire protection conformity in accordance with EN 45545 and first-class production in accordance with EN 15085 are guaranteed. From converter cooling with coolant and transformer oil cooling to combined systems - including selectable connection positions on the cooler, various electrical wiring concepts and accessories - everything is available. The accessories extend far beyond protective grilles, filters, expansion joints and sensors.

From the compact cooling unit with low weight to the meter-high cooling tower, we are your reliable partner on the rail. We develop and produce underfloor as well as roof cooling systems and cooling systems installed in trains according to your wishes. The components developed by AKG are used in

- Trams

- Electrically powered trains (regional and high-speed trains)

- Diesel locomotives

- Magnetic levitation trains

Innovative Cooling Solutions for Modern Rail Vehicles

At AKG, we pride ourselves on delivering innovative cooling solutions that meet the evolving demands of the rail industry. Our technologies are designed to enhance the efficiency and reliability of rail vehicles, ensuring optimal performance under all operating conditions. Whether it's a high-speed train racing across continents or a city tram navigating busy streets, our cooling systems are engineered to maintain the perfect temperature balance, preventing overheating and maximizing operational uptime.

Our Key Advantages:

- Custom Engineering: Tailor-made solutions to fit specific customer requirements.

- High Efficiency: Advanced heat exchanger designs that ensure superior cooling performance.

- Reliability: Robust systems built to withstand the harshest environmental conditions.

- Compliance: All products meet stringent international safety and quality standards, including EN 45545 and EN 15085.

- Sustainability: Eco-friendly technologies that contribute to reducing the carbon footprint of rail transport.

Our commitment to innovation and excellence positions AKG as a trusted partner in the rail industry, providing solutions that not only meet but exceed our clients' expectations.

AKG – efficient cooling systems contributing to a greener and sustainable world

AKG supports the decarbonization of the global economy with efficient cooling and thermal management systems for alternative drive concepts and clean energy for customers in selected industries, such as wind energy, electronics and fuel cell cooling. It has always been our goal to improve thermal solutions, starting in 1919 with automotive cooling over the recent past with the cooling of combustion engines in different applications until today’s Green Thermal Solutions. We believe that we can help our customers all over the world to meet their “net-zero” emission targets. AKG Green Thermal Solutions is our approach to help creating a sustainable future.

Cooling System for Fuel Cell Vehicles

AKG has a wide range of heat exchangers for fuel cell cooling applications. These solutions include a LightWeight cooler for coolant cooling, liquid cooled cold plate for power electronics and liquid cooled compact coolers for hydrogen pre-heating & charge-air cooling. AKG’s technical expertise in integrating different systems not only offers a flexible design to our customers, but is also meeting all the demands of fuel cell applications.

A fuel cell converts hydrogen and charge air into electric energy with air and water as exhaust. It needs to be cooled with a low conductive coolant to prevent short circuits. Vacuum brazed and de-ionized heat exchangers are well suited for operation with low conductive coolant.

Fuel Cell Indirect Cooling

In indirect cooling, there are two separate coolant circuits – regular coolant and low conductive coolant. The low conductive coolant circulates between the fuel cell and a liquid-to-liquid heat exchanger (stacked shell cooler) where the low conductive coolant is cooled by a regular coolant. The regular coolant circulates through the stacked shell cooler, followed by charge air cooler, hydrogen pre-heater. The coolant is finally cooled by the ambient cooler and the cycle repeats.

AKG Product Portfolio for Fuel Cell Cooling

- Stacked Shell Cooler

- LightWeight Cooler

- Compact Cooler

- Cold plate

Benefits of indirect cooling compared to direct cooling

- Conductive particles are reduced as the circuit is smaller sized

- Reduced volume of expensive low conductive coolant

- Less ionic emissions resulting in lower change interval for ion exchanger

- Components of the coolant circuit can be produced with less requirements complying with electrical conductivity

Electronic Cooling

Power electronics are inevitable in most modern systems, such as inverters and converters for renewable energies as well as electric drivetrains. Even though the efficiency is very high, there are still local heat loads, which need to be cooled to achieve a better performance and longer lifetime. With our product portfolio in electronics cooling and many years of proven and optimized design, we are able to achieve a high performance and homogenous low temperature for the sensitive power electronics.

AKG Solutions for a Sustainable Future

-

Brochures

Rail Vehicle

Rail Vehicle